Small Dry Ice Pellet Maker Description

Dimensions(L*W*H) : 142.8cm×77cm×118.8cm

Weight:450kg

Capacity: One Cylinder 3 mm 35kg/hr Two Cylinder 3 mm 70kg/hr

Pellet Size: standard 3mm, 16mm(need to buy a die plate)

Power Supply :2.2kw/hr, 220VAC, 50HZ

Power System: Hydraulic system

Oil Pressure:22Mpa

Inlet pressure:14-22bar

Dry Ice Maker Photos

HP80A Dry Ice Pelletizer: An Efficient and Convenient Dry Ice Production Marvel

In the field of dry ice production, the small dry ice pellet maker HP80A stands out as an ideal choice for numerous enterprises and users with its remarkable features, breaking through traditional limitations and boasting a series of outstanding advantages.

dry ice maker

This model has a compact design and a small footprint. In the production sites, where every inch of space is precious, it does not require a large area to be reserved. It can be flexibly placed in the corner of the workshop or in a compact work area without taking up too much valuable space. This provides more convenience for the site layout of enterprises, especially for small and medium-sized enterprises with limited site resources, enabling more efficient space utilization.

Dry Ice Maker Highlights

1. Flexible Voltage Adaptation and Reduced Operating Costs

The dry ice pellets machine HP80A dry ice pelletizer only requires a 220V conventional voltage, eliminating the dependence on industrial voltage. This feature greatly simplifies the electrical connection of the equipment. Ordinary commercial premises or small-scale factories can install and use it without complex circuit renovations, saving the high costs associated with adapting to industrial voltage, such as the purchase of transformers and the cost of circuit laying and modification. It enables more users to easily start their dry ice production business, significantly reducing the entry barriers.

2. Innovative Dual-Chamber Structure for Diverse and Efficient Production

The dry ice pellet maker HP80A features a unique dual-chamber structure design, bringing great flexibility to dry ice production. The two chambers can operate independently, meaning that different specifications of dry ice pellets can be produced simultaneously to meet diverse market demands. For example, at the same time, small particles suitable for cleaning precision electronic equipment can be produced on one side, while larger particles for food preservation can be produced on the other side. This not only greatly improves production efficiency and effectiveness but also reduces equipment procurement costs, making one machine function as two.

3. Compact Body Design for Optimized Space Utilization

This model has a compact design and a small footprint. In the production sites, where every inch of space is precious, it does not require a large area to be reserved. It can be flexibly placed in the corner of the workshop or in a compact work area without taking up too much valuable space. This provides more convenience for the site layout of enterprises, especially for small and medium-sized enterprises with limited site resources, enabling more efficient space utilization.

4. Stable and Reliable Performance for Continuous Production

The dry ice pelletizer HP80A has excellent stability. During long-term continuous operation, it can maintain a stable running state, minimizing downtime due to malfunctions. Its stable mechanical structure and sophisticated manufacturing process ensure the smooth cooperation of all components, guaranteeing the continuity and consistency of dry ice production. This reduces maintenance costs and the risk of production interruption, providing users with reliable production support and creating more value.

IS09001 CERTIFICATE

ISO 45001

CE DRY ICE BLASTING MACHINE

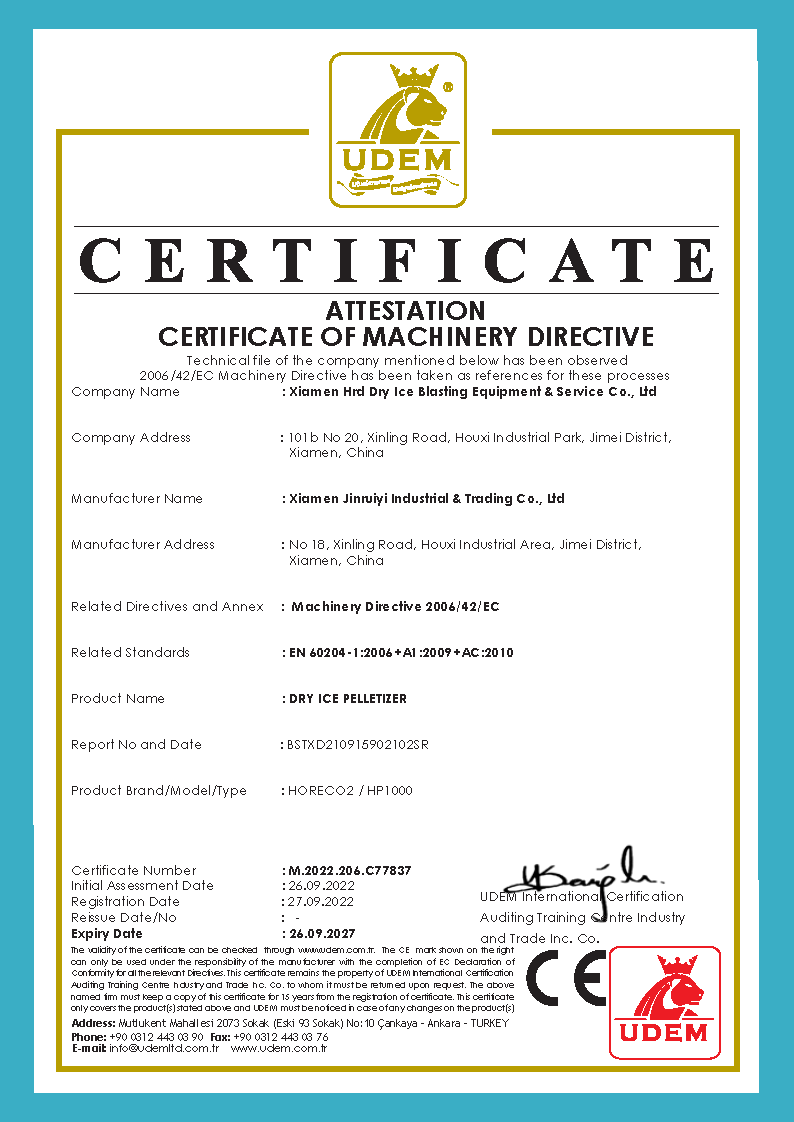

CE DRY ICE PELLETIZER