Challenges In Dry Ice Production

1. Shortage and instability of raw material supply.

2. Many raw materials are wasted in dry ice production.

3. A large amount of CO2 is released into the air, threatening workers' health and life safety.

4. High production costs, Intense market competition, Low profit margins.

5. Traditional CO2 recovery unit requires a large investment, high power consumption, occupies a large area.

Benefits of adding a CO2 Recovery Unit

1.Greatly reduce carbon dioxide consumption and stabilize dry ice supply capacity during seasons of raw material shortage.

2. High conversion rate, reducing raw material costs.

3. Reduce carbon dioxide emissions and promote green development.

4. Reduce raw material consumption costs and increase profit margins.

5. Reduce carbon dioxide emissions in factories and protect the lives and health of workers.

Dry Ice Production Cost Comparison

| Pelletizer | Pelletizer with CO2 Recovery System |

Production Capacity | 300 | 300 |

Daily Dry Ice Production (KG) | 2400 | 2400 |

Working Time per Day (Hours) | 8 | 8 |

Conversion Ratio | 2.35:1 | 1.35:1 |

LCO2 Consumption Per Day (KG) | 5640 | 3240 |

Cost of LCO2 Per KG | $0.28 | $0.28 |

Cost of LCO2 Per Day | $1,579.20 | $907.20 |

Total Amount Saved Per Day | $0.00 | $672.00 |

Total Amount Saved Per Year | $0.00 | $168,000.00 |

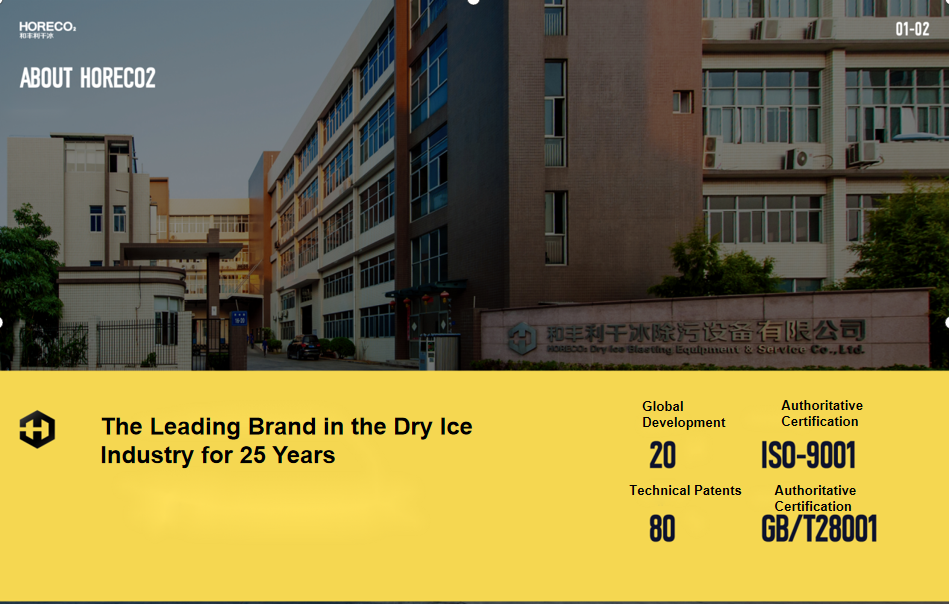

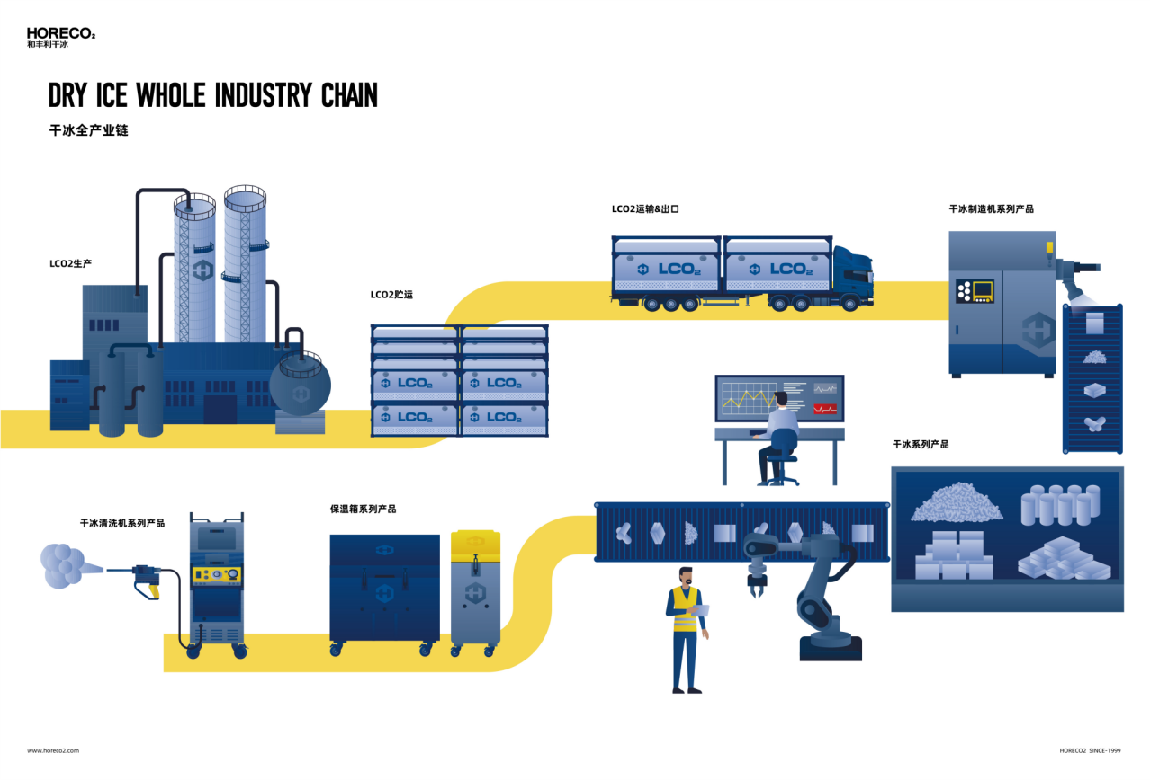

Xiamen Horeco2 Dry Ice Blasting Equipment & Service Co., Ltd,established in 1999, it is the only groupcompany in China that builds a full industrial chain centered around dry ice.Its industries cover Carbon Dioxide Production and Recycling,Dry Ice Production and Application, Dry Ice Cleaning Machines, Dry Ice Manufacturing Machines, Dry Ice Box Manufacturing, and Cold Chain Transportation

Development, etc.

As a leader in dry ice innovative technology, Horeco2 has been rooted in the dry ice industry for 25 years.Currently, it has established 20 dry ice manufacturing factories globally and possesses a full set of independent intellectual property rights as well as a professor-level R&D team

Corporate Values

Environmental Protection:

We recycle industrial waste CO₂ and transform it into value-added products—dry ice. As a recyclable form of CO₂, dry ice replaces environmentally harmful traditional cleaning methods and reduces energy consumption in cold chain logistics. Additionally, the use of dry ice does not count toward corporate carbon emission quotas, helping businesses improve their ESG (Environmental, Social, and Governance) scores.

Employee Safety:

Dry ice cleaning replaces traditional chemical solvent-based cleaning methods, minimizing secondary pollution and providing employees with a greener, safer working environment.

Advanced Dry Ice Technology Leading the Industry:

HORECO₂ boasts a professor-level R&D team, collaborates with multiple universities, and operates a postgraduate research station. To date, HORECO₂ has obtained over 80 patented technologies, continuously driving innovation in China’s dry ice industry.

High-Quality Products Delivering Value to Customers

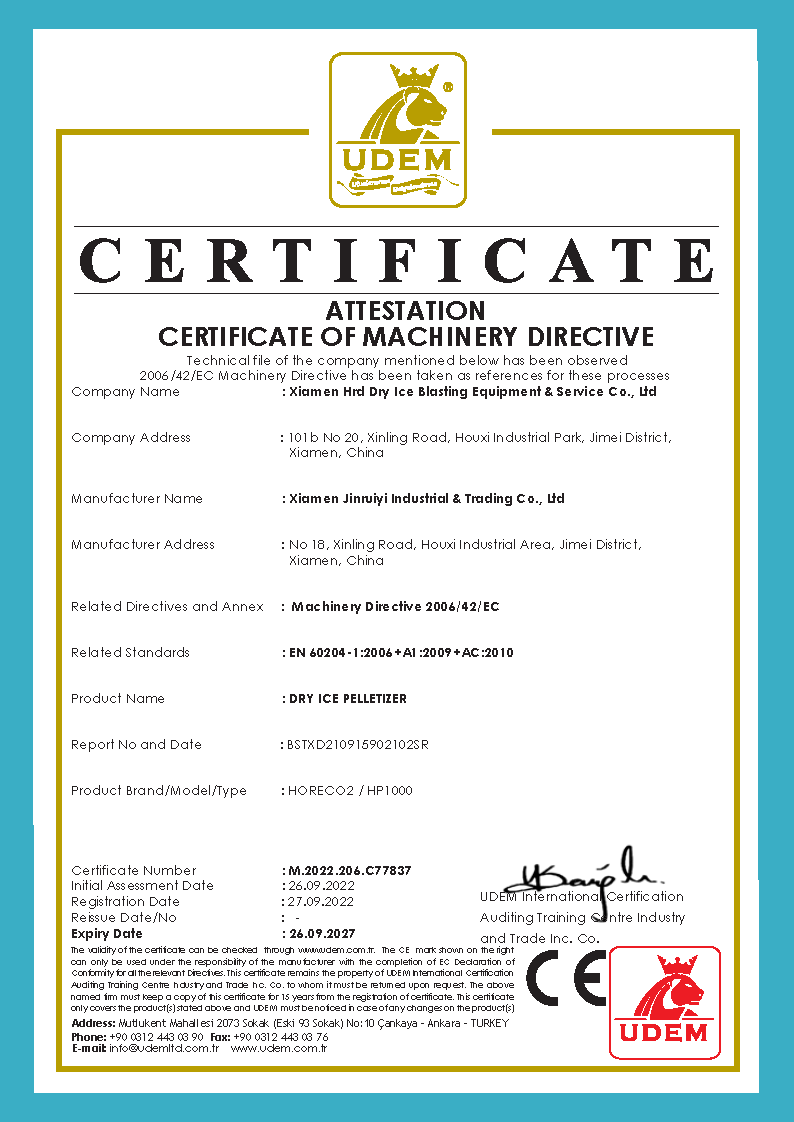

With nearly 25 years of production experience and stringent quality control, HORECO₂ has achieved ISO9001:2008 Quality Management System and GB/T280001-2001 Occupational Health and Safety Management System certifications. All products are also CE-certified by SGS. HORECO₂ delivers long-term value to customers through its high-quality products.

IS09001 CERTIFICATE

ISO 45001

CE DRY ICE BLASTING MACHINE

CE DRY ICE PELLETIZER