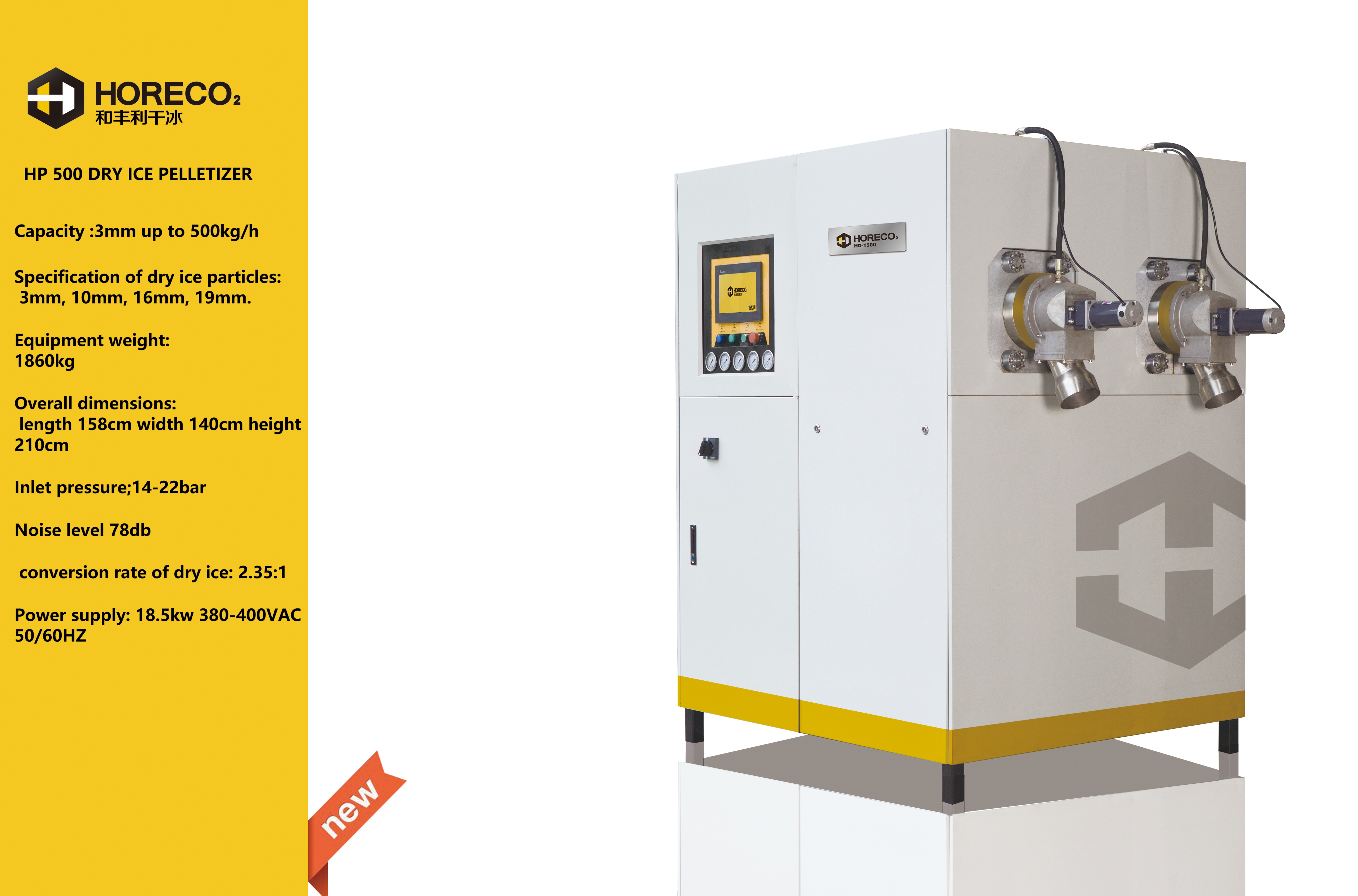

Dry Ice Pelletizer HP500

Technical Datasheet:

The industrial dry ice maker HP500 is a top-tier model renowned for its remarkable stability, making it a reliable choice for various industrial applications. One of its most outstanding features is its high-level stability. This not only ensures continuous operation but also reduces maintenance costs and production disruptions.

Capacity 3mm up to 500kg/h

Specification of dry ice particles: 3mm, 10mm, 16mm, 19mm.

Equipment weight: 1860kg

Overall dimensions: length 158cm width 140cm height 210cm

Inlet pressure;14-22bar

Noise level 78db

Liquid carbon dioxide conversion rate of dry ice: 2.35:1

Power supply: 18.5kw 380-400VAC 50/60HZ

Cost Comparison

The dry ice conversion ratio of the dry ice rice pellets machine HP500 reaches 2.35:1.

This high conversion efficiency means that it can transform a large amount of liquid carbon dioxide into solid dry ice with minimal waste, making the production process more cost-effective.

| Other Supplier's Pelletizer | HORECO2 Pelletizer | Pelletizer with CO2 Recovery Unit | |

| Production Capacity | 500 | 500 | 500 |

| Daily Dry Ice Production (KG) | 4000 | 4000 | 4000 |

| Working Time per Day (Hours) | 8 | 8 | 8 |

| Conversion Ratio | 2.5:1 (40%) | 2.35:1 (42.5%) | 1.35:1 |

| LCO2 Consumption Per Day (KG) | 10000 | 9400 | 5400 |

| Cost of LCO2 Per KG | $0.25 | $0.25 | $0.25 |

| Cost of LCO2 Per Day | $2,500.00 | $2,350.00 | $1,350.00 |

| Total Amount Saved Per Day | $0.00 | $150.00 | $1,150.00 |

| Total Amount Saved Per Year | $0.00 | $45,000.00 | $345,000.00 |

With a capacity of 500 kg/h, the industrial dry ice maker HP500 produces dry ice with a density of up to 1500 kg/m³. This high-density dry ice is especially suitable for dry ice cleaning applications. When used in dry ice cleaning, the high-density dry ice pellets can impact the surface of the object to be cleaned with greater force, effectively removing stubborn dirt, grease, and other contaminants without causing damage to the surface of the object.

Another unique design feature of the dry ice rice machine HP500 is that it has two cavities and ice cylinders, which can be operated independently. This independent operation mode provides more flexibility in production. For example, if one cavity needs maintenance or adjustment, the other can continue to operate, ensuring that production is not completely halted. The industrial dry ice makers also allow for different production requirements to be met simultaneously, such as producing different sizes or qualities of dry ice pellets in each cavity.

HORECO2 Xiamen Factory

The HORECO2 Xiamen Factory is the headquarters of the HORECO2 Group. It consists of an office building and two equipment R&D and production workshops. The factory is also the R&D and production base for HORECO2 dry ice equipment.

Dry Ice Insulated Container Factory

HORECO2 invested RMB 100 million in 2016 to establish the ICECON brand, The factory covers an area of 30,000 square meters focusing on the production of dry ice insulated containers and cold chain insulated container products.

HORECO2 Thailand

After years of development, HORECO2 Thailand Factory has become the largest producer of dry ice pellets in Thailand, serving more than 1,000 industrial and commercial customers in Thailand.

Not only does it provide customers with high-quality dry ice but also provides dry ice equipment for Thai industrial and commercial customers.

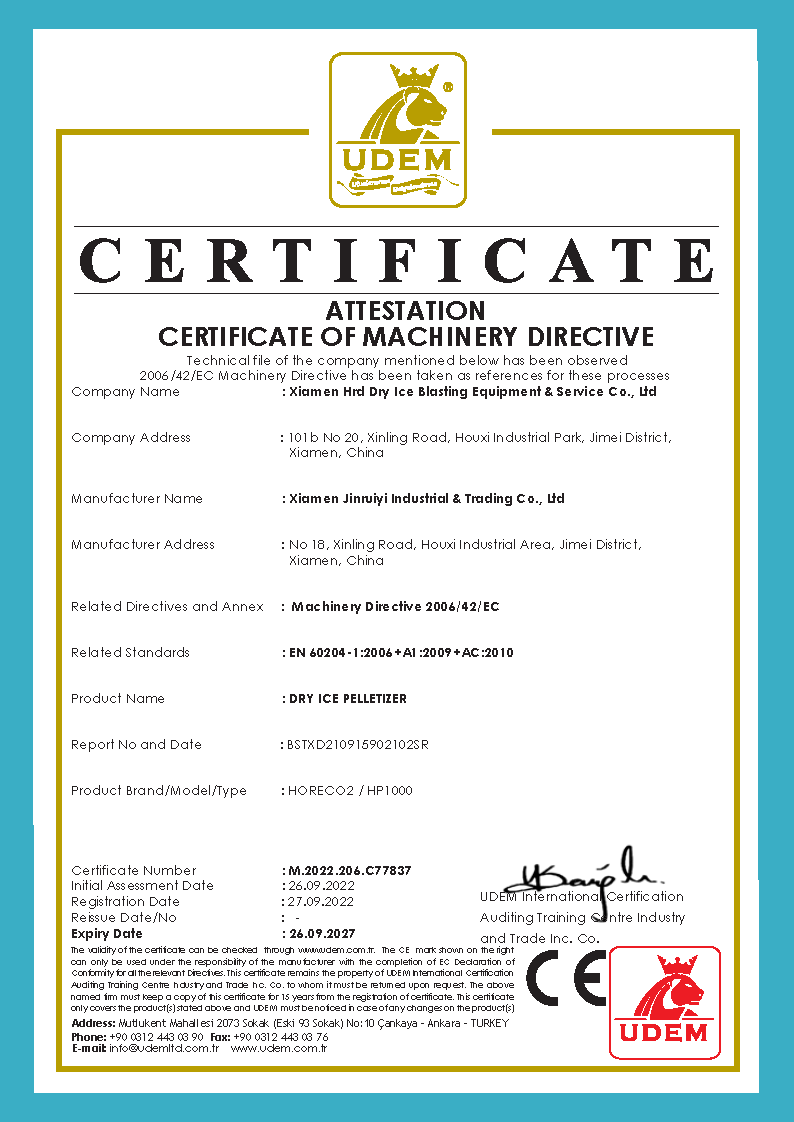

Certificate

IS09001 CERTIFICATE

ISO 45001

CE DRY ICE BLASTING MACHINE

CE DRY ICE PELLETIZER

FAQ

Q:Are you a trading company or manufacturer?

A:Yes, We are a factory, all machine is made by ourselves and we can provide customized service according to your requirements.

Q:Can you guarantee your quality?

A:Of course. We are the manufacture factory. More importantly, we put a high value on our reputation. Best quality is our principle all the time.

Q:What are your Installation Services?

A:Usually, we will send our engineer to your factory. For the Cleaning machine, The user manual and videos about the operation of the machine will be sent to you as well.

Q:How could I get the spares on machines?

A:We will send extra sets of easily broken spares and accessories etc. Non-artificial damaged spares will be sent freely and shipping-free during 1-year warranty

Q:If we have a very special request for the production line, could you help me to do the design?

A:Experienced mechanical designer customized design provided.