PRODUCT SPECIFICATIONS

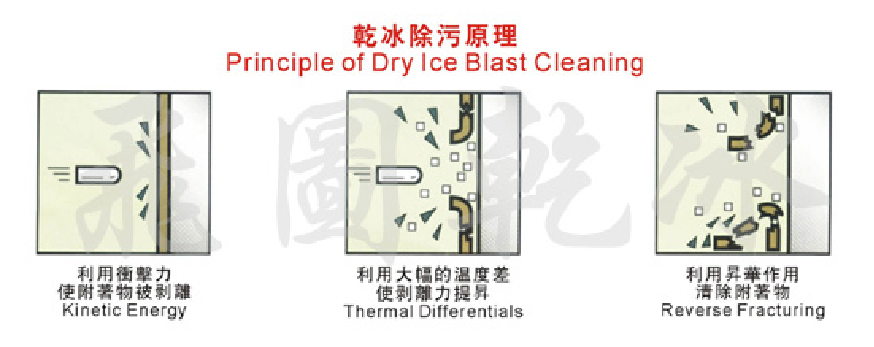

Dry Ice Cleaning Principle

As the pellets of dry ice impact onto the surface to be treated, a thermal differential is established between the substrate and the contaminants. Meanwhile the pellets sublimateand these gaseous molecules of CO₂, enter through the pore spaces between thecontaminate and the substrate. Since the volume expand 800 timesinstantaneously, thus pushing the contaminate from underneath.further assistingin the removal process. Comparing with other blasting methods, the Kinetic Energy(KE=1/2 mv²) of dry ice pellets is not the only contributing factor,so we can vary the blasting pressure for heavy slag removal or even sensitive substrates such as delicate semiconductors andcircuit board cleaning.

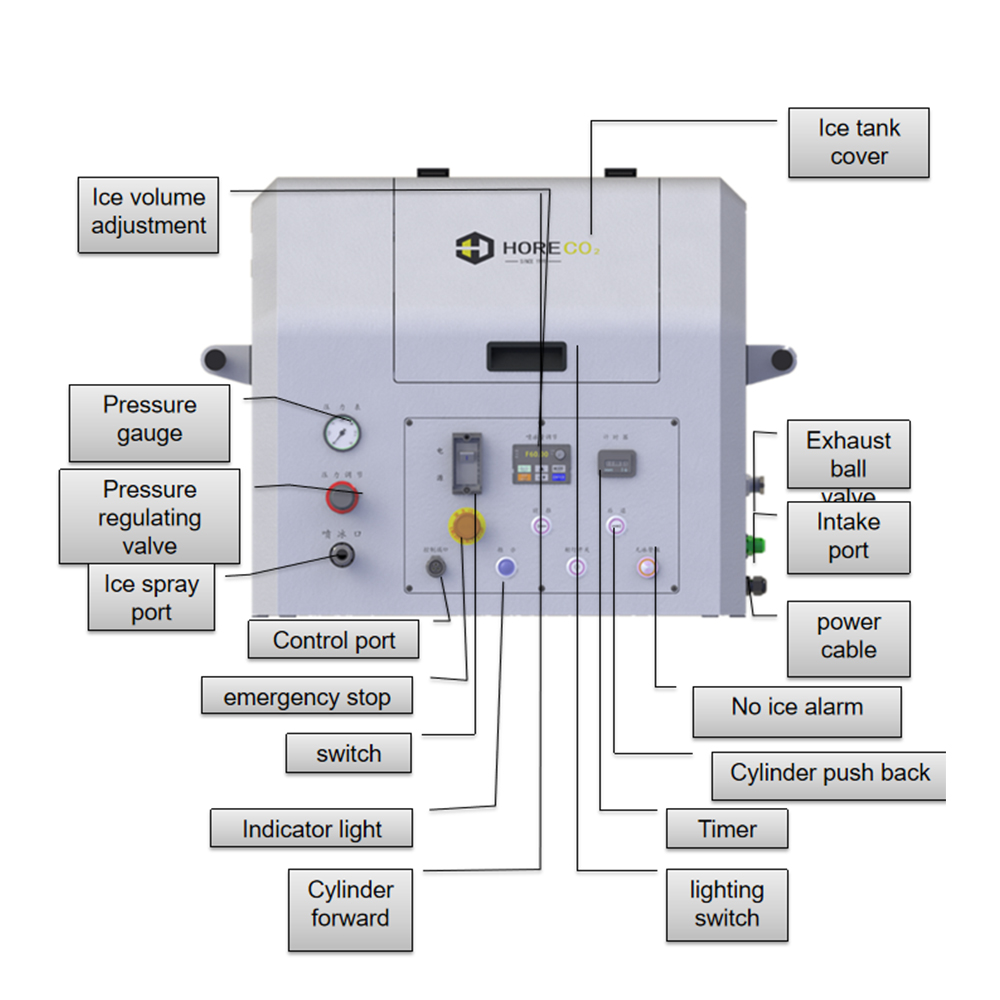

CC-E

Techinical Parameter

The ice mode: Single-tube

Hopper capacity: less than 9KG*Variable feed rate: 0- 650g/min

Compressed air pressure: 1-7 bar

Compressed air flow required: 1-1.15 m3/min

Dimensions (L X W X H) 695mm×425mm×525mm

Weight: :73KG

Power :220VAC, 50 HZ, 3 Amp

Application in different industry:

*The special flow channel setting of this device enables smoother ice discharge and more uniform particles, which is mainly reflected in the following aspects:

* Burrs removal: The device can remove plastic burrs, electroplating dust, etc. from precision components in one step, saving time and effort.

* Molds: It quickly and efficiently cleans precision rubber molds, silicone molds, aluminum alloy die-casting molds, and removes dirt on production lines.

*Electronics and motors: The device allows for dry cleaning of circuit boards, photocopiers, motors, generators, etc. without causing short circuits or electric leakage.

*Automotive: It can remove engine and undercarriage oil stains without water pollution. Cleaning the moulds the car parts,doing the Pre-coating treatment ect.

* Food industry: The device enables low-temperature dry cleaning of ovens, conveyor belts, baking molds, etc., eliminating opportunities for bacterial growth.

*Ships: It is used for cleaning condensers and heat exchangers, which is cleaner than using high-pressure water.

*Home appliances industry: It can handle tasks such as polyurethane foam cleaning and glue overflow.

* Glass panels: The device clears dust, residue, oil stains, etc. from glass surfaces

Related Products

Show Room

Certificate

Project in India

Project in Russia

Company Profile

HORECO2 INTRODUCTION

Established in 1999, HORECO2 Dry Ice Blasting & Service Co., Ltd is the earliest enterprise of China to be committed to the application of dry ice. After decades of development, it has formed complete industrial structural chains of research and development, manufacture, sale and after-sale.As an industrial benchmark of dry ice, we have a doctoral team. Our major products mainly include dry ice blasting machines, dry ice production equipment, dry ice insulated containers and related smart products; 18 dry ice production factories are distributed around the globe, providing complete dry ice delivery service network, and sincerely presenting you with a use experience of high cost performance.

Corporate Values

Environmental Protection:

We recycle industrial waste CO₂ and transform it into value-added products—dry ice. As a recyclable form of CO₂, dry ice replaces environmentally harmful traditional cleaning methods and reduces energy consumption in cold chain logistics. Additionally, the use of dry ice does not count toward corporate carbon emission quotas, helping businesses improve their ESG (Environmental, Social, and Governance) scores.

Employee Safety:

Dry ice cleaning replaces traditional chemical solvent-based cleaning methods, minimizing secondary pollution and providing employees with a greener, safer working environment.

Advanced Dry Ice Technology Leading the Industry:

HORECO₂ boasts a professor-level R&D team, collaborates with multiple universities, and operates a postgraduate research station. To date, HORECO₂ has obtained over 80 patented technologies, continuously driving innovation in China’s dry ice industry.

High-Quality Products Delivering Value to Customers:

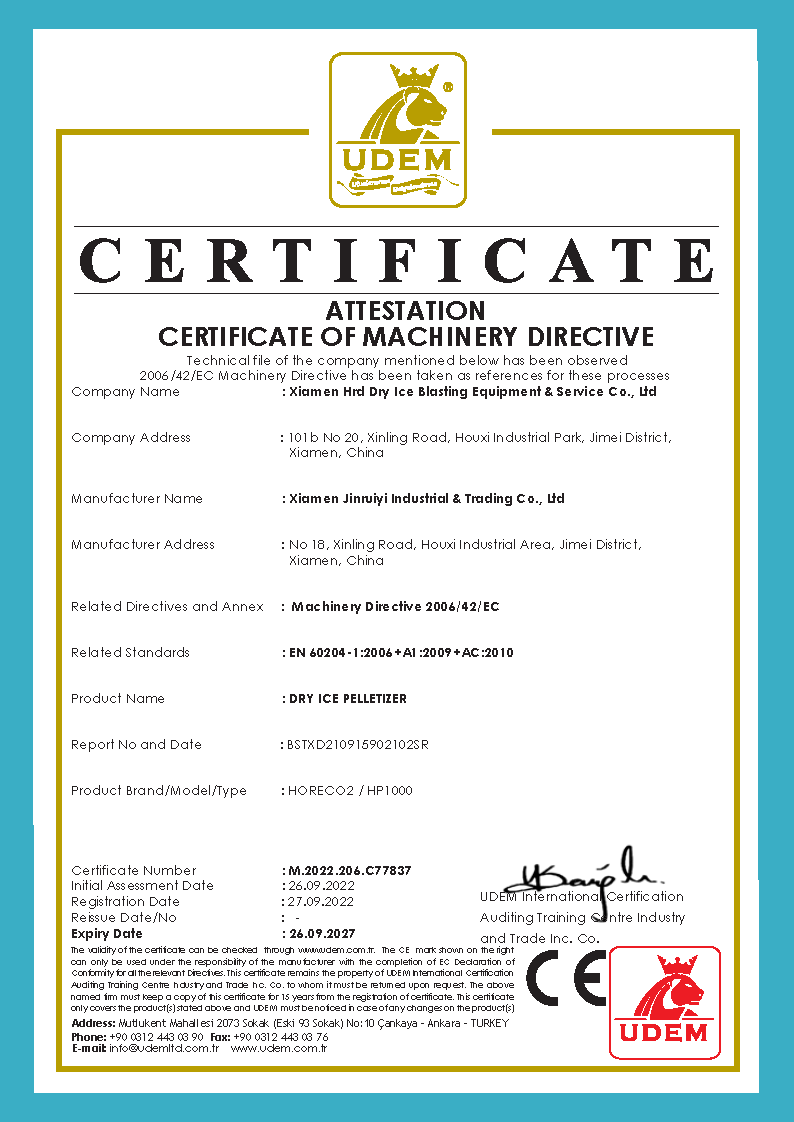

With nearly 25 years of production experience and stringent quality control, HORECO₂ has achieved ISO9001:2008 Quality Management System and GB/T280001-2001 Occupational Health and Safety Management System certifications. All products are also CE-certified by SGS. HORECO₂ delivers long-term value to customers through its high-quality products.

Exhibition

Product packaging

IS09001 CERTIFICATE

ISO 45001

CE DRY ICE BLASTING MACHINE

CE DRY ICE PELLETIZER

FAQ

1.Are you manufacturer or trader? What's your main products?

A: We are manufacturer of Dry ice equipment . Our main products are including Dry Ice Blasting Machine ,Dry Ice Pelletizer ,Dry Ice Block Machine ,Dry Ice recovery system ,dry ice packing line ,dry ice containers,ect.

2.What's the delivery time?

A:The delivery is according products,please confirm with the sales.Usually ,the delivery time is from 7-60 days according to products.