Working Principle of the Dry Ice Machine

The dry ice machine operates by spraying liquid carbon dioxide (CO₂) into an atmospheric pressure chamber. A portion of the CO₂ absorbs significant cold energy under atmospheric pressure, forming solid powdered dry ice, while the remaining portion releases cold energy and reverts to gaseous CO₂. The solid powder is compressed into dry ice pellets via a hydraulic system, while the excess gas is typically emitted into the atmosphere. Approximately 42% of the CO₂ is converted into dry ice, leaving 58% wasted during the process. This inefficiency is inherent to the natural physical principles of dry ice formation and cannot be altered.

Innovation: CO₂ Liquefaction and Recovery System

The CO₂ Liquefaction and Recovery System developed by HORECO2 is the cornerstone of its cost-saving technology. This system operates through three key steps:

Recovery: Capturing CO₂ gas released during production.

Liquefaction: Cooling and compressing the gaseous CO₂ back into liquid form.

Reuse: Directly recycling the liquid CO₂ into the dry ice production cycle.

Advantages of CO₂ Recovery

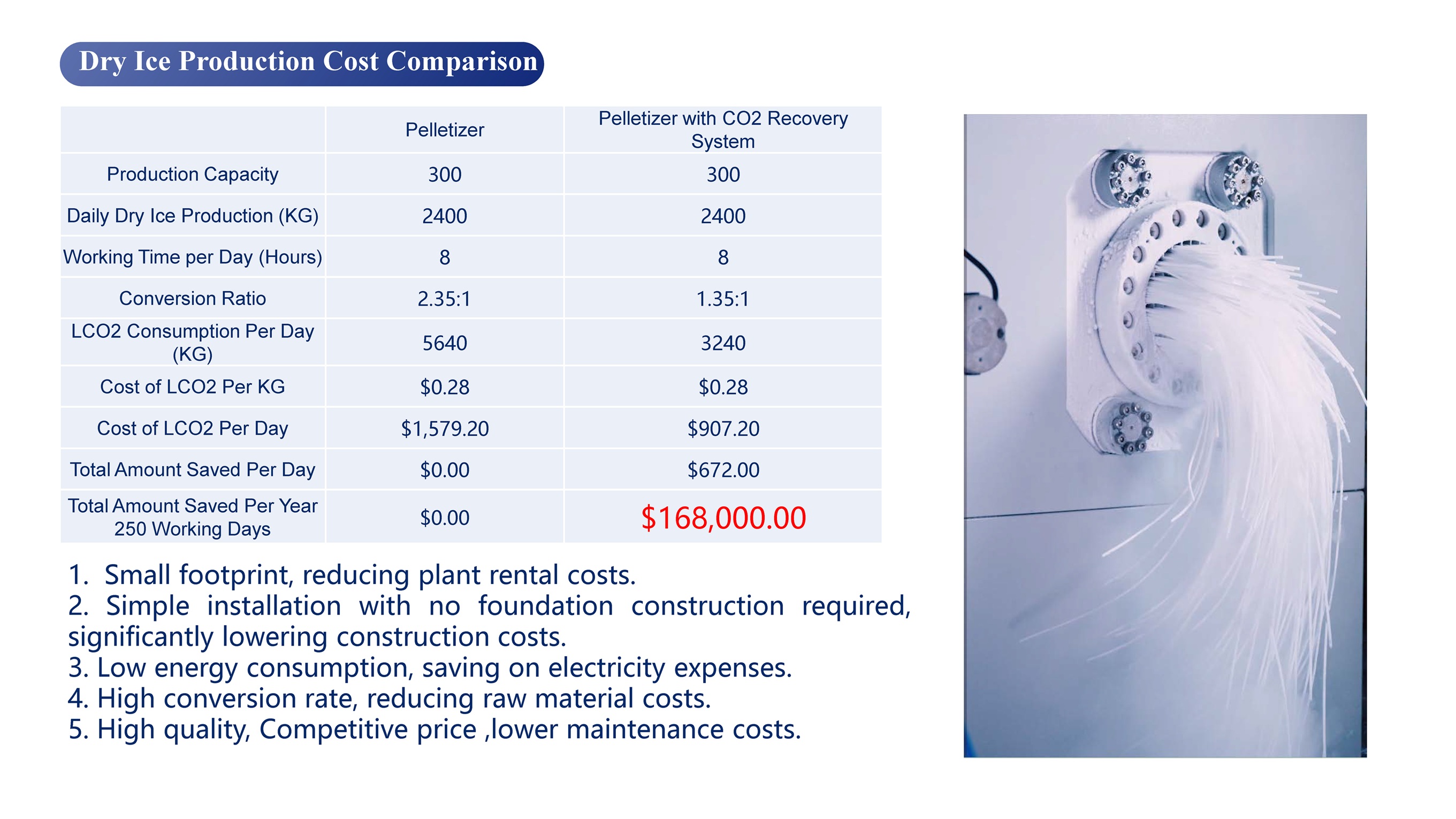

Cost Reduction: By recycling CO₂, the system slashes dry ice production costs by ~40%.

Increased Output: The same volume of liquid CO₂ yields 70% more dry ice compared to traditional methods.

Carbon Footprint Reduction: Minimizes CO₂ emissions by reusing gas that would otherwise be wasted.

Customization: The recovery system can be tailored to meet specific client needs.

Modular Design: Easily integrates with dry ice pelletizers from any brand.

Dry ice has become an increasingly popular high-efficiency cooling medium in the Industrial Production and Logistics Sectors. However, traditional dry ice manufacturing processes are often associated with high costs and low production efficiency. The HORECO2 Dry Ice Machine, with its innovative CO2 Liquefaction and Recovery System, has revolutionized the dry ice manufacturing industry by reducing production costs by 40%.

Model Selection

Model Selection

HORECO2 offers three models to cater to diverse production scales:

RS 160: Max liquefaction capacity of 160 kg/h (ideal for small to medium operations).

RS 320: Max liquefaction capacity of 320 kg/h (suited for medium to large-scale needs).

RS 600: Max liquefaction capacity of 600 kg/h (designed for industrial-level production).

How Does It Achieve a 40% Cost Reduction?

The 40% cost reduction stems primarily from the CO₂ Liquefaction and Recovery System:

Reduced Raw Material Demand: Recycling CO₂ cuts reliance on new CO₂ supplies.

Higher Yield Efficiency: Increased dry ice output lowers per-unit production costs.

Flexible Integration: Modular design and customizable configurations optimize operational efficiency and cost-effectiveness for diverse client requirements.